CNC Turning

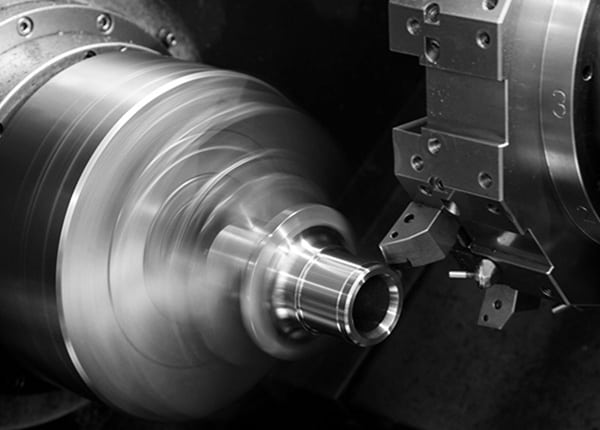

CNC Turning

DKW Machine Precision offers the highest standard in CNC lathe turning services. The company’s expert CNC programmers and machinists deliver accuracy, precision, and the highest quality.

Manuel Turning

DKW Machine Precision machinists also provides unmatched expertise for a wide range of operations when manual control is ideal. Manual turning can cost less, provide quicker response, and no delays for our customers.

Prototype Turning

Prototype turning parts on CNC turning centers allows for a wide range of complexities, sizes, and material types. CNC turning is a manufacturing process where bars of material are held in a chuck and rotated while a tool removes excess material to create a desired shape.

Why Choose DKW Machine Precision for CNC Turing Services?

DKW Precision Machining creates partnerships designed to increase productivity and reduce total costs for its customers. Our team of professionals provides CNC turning services at a competitive price that impacts the bottom line. Additional advantages of partnering with us include but are not limited to:

- Innovative and cost-effective solutions designed to increase productivity and save time and money.

- The highest quality engineers and machinist in the industry.

- Streamlined processes designed to provide expertise and short lead times.

- In-house capabilities providing CNC turning services.

- Safe and green business practices designed to support workplace and environmental safety.

Quality Control

DKW Precision Machining conducts state-of-the-art turning for a variety of materials to ensure it is clean and useable. We take quality control very seriously, putting every manufactured piece through an extensive inspection process. When it comes to producing high-quality machined parts, precision and accuracy are essential to ensure the best functionality of a component, and we deliver it.

Our commitment to quality is possible by using the highest quality inspection equipment including measuring machines, comparators, and the highest quality tooling, allowing for the best precision and finish. You can rely on DKW Precision Machining for the best order fulfillments and precision machining.

Computer Software

DKW Precision Machining uses the latest version of SURFCAM 3D programming software to meet our machining needs. We utilize Smartshop Manager software for all our estimating, scheduling, and accounting requirements. This allows us to provide our customers with quality products, competitive pricing, and on-time deliveries. We also utilize SolidWorks.

Feel free to contact us anytime.

Best Machining Services in Manteca, CA

DKW Machine Precision offers the highest quality milling services in the industry

Call Us Now (209) 824-7899

Materials

- Acrylic/Plexiglass

- ABS

- Delrin/Acetal

- Kel-F

- Lexan/Polycarbonate

- Teflon

- PVC

- Polyimide/Vespel

- Torlon

- Bar Seal

- Aluminum

- Brass

- Bronze

- Copper

Industries We Serve

At DKW Precision Machining’s shop, we have an entire spectrum of industries that depend on our services. Some of these include:

- Electronics

- Medical

- Aerospace

- Underwater Exploration

- Laboratory Equipment

- Industrial Equipment

- Linear Motion

- Packaging

- Semi-Conductor

- Food Processing

- Unmanned Aerial Systems

- Unmanned Controlled Systems

- Surveillance & Reconnaissance

- Rapid Services Manufacturing

- Contract Manufacturing

Frequently Asked Questions

CNC milling (Computer Numerical Control Milling) is a machining process which utilizes computerized controls and rotating cutting tools to remove material from the workpiece to produce a specific product or part. This process is suitable for machining a wide range of materials, such as metal, plastic, glass, and wood, and producing a variety of custom-designed parts and products.

Turning is as a machining process where bars of metal are rotated while a tool is used to remove excess material until the desired shape is reached.

Manual Turning is a process in which a cutting tool shapes a workpiece while it moves and requires constant operator supervision of the lathe. A Lathe is a machine that shapes workpieces while they are rotated

Live tooling produces a reverse effect and brings a mill into that CNC lathe. The live tool is merely an end mill within the lathe component.